For our long term time lapse customers, the SOLAR and DRY enclosures are critical products to ensure successful projects. And while both enclosures have been among our most popular products, our engineering team worked to make some important improvements to make these products even better. We give you a behind-the-scenes look at these changes below.

The Challenge

To give our users a simple robust method to mount their SOLAR and DRY enclosures. We wanted to improve the first version of these products, which were popular, but not field serviceable.

Improvement Objectives

- Incorporate a Gore-Tex vent to reduce condensation

- Provide multiple mounting points and methods for straps, tripod bolts, and metal bands

- Reduce all holes used to attach features to the enclosure to a minimum, and move them to the bottom where possible, to prevent water ingress

- Make all components modular, and field serviceable

- Make the system tough enough to withstand extreme weather conditions without shifting position or leaking

- Make the system easy to manufacture

- Make it easy to position the solar panel for optimum light energy exposure

Glimmer of an Idea

We knew the flanges at the bottom of the enclosure would be a great starting point. We could attach the bracket there, and we could do it without creating any holes to the inside. By creating holes in the flanges, we could use machine screws through to fasteners in the bracket. We needed to check our ideas, so we went to a quick cardboard mockup.

But how to attach to the top, without creating a hole there, which would be the worst place if the enclosure was wet? In the end, we decided that since the finished unit is small and light, we would sacrifice the use of the enclosure handle. A drill hole for a Plastite screw would be drilled into the handle, permanently trapping it against the bracket. Now we had a bracket design that was tough and useful, and attached securely while preventing water from leaking in and damaging our user's cameras.

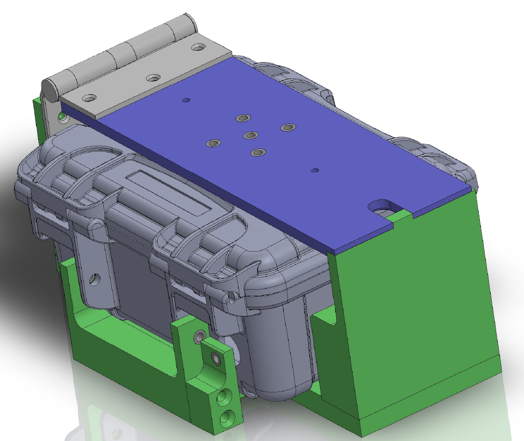

Time to get the design into 3D CAD, so we could drive metal forming!

And make some tools to ensure easy and consistent manufacturing…

After some hard work, our goals were achieved, and the new units were put into use, to enthusiastic reviews by our customers.

As may be seen here, these units don’t get kid glove treatment. With hundreds now in service, we have not received a single report of failure.

To finish off the product, we added a modular Swivel Mount Kit, giving our users exceptional mounting flexibility with the twist of a knob! Now you can easily achieve the exact desired filming angle.

Customer feedback was a catalyst for several of these important improvements. We'd love to hear your thoughts on your experience with our products.

For all product updates, be sure to look out for our blog posts by signing up to our newsletter here.