Blog

Looking for a solar-powered time-lapse camera that can survive winter? This guide breaks down what to look for, plus real uptime tools that take out the guesswork.

- Camera Setup

- Construction Time Lapse

- DataLens

- Educational

- GoPro Time Lapse

- SolarUp

- Time Lapse

- Tips

- UpBlink

- January 26, 2026

- 5 min read

DSLRs deliver cinematic results, but are they overkill for construction time-lapse in 2026? Compare DSLR vs. purpose-built 4K systems like DataLens & SolarUp.

- January 06, 2026

- 3 min read

Keep your construction cameras running reliably through freezing weather. This practical guide covers the critical challenges of cold, power loss, optics, and signal, and provides practical solutions. Learn how to choose cameras rated to -4°F (-20°C), optimize solar power for short days, and leverage automated and on-demand images to safely reduce expensive, routine winter site visits.

- December 17, 2025

- 5 min read

- Construction

- Construction Photos

- Construction Time Lapse

- GoPro Time Lapse

- Outdoor

- Photography

- Photos

- Time Lapse

- Tips

- Video

- November 11, 2025

- 3 min read

Brookfield’s Nicole Ivers explains how owners cut serious incidents: design hazards out, use tech to reduce exposure, track SSI, and run no-blame culture.

- Construction

- Construction Monitoring

- Construction Photos

- Construction Time Lapse

- Educational

- Onsite Insight Series

- Tips

- September 19, 2025

- 4 min read

Simply put, your interval should match the speed of action you want to capture. The interval determines the length of the final video and how smooth the motion appears. While the idea is simple, execution depends on several factors.

- August 28, 2025

- 3 min read

Installing a time-lapse system on your construction site is one of the best ways to track progress, keep stakeholders informed, and create a lasting record of your project. But with so many camera options available, how do you know which one is the right fit?

- August 20, 2025

- 4 min read

Choosing the right camera angle isn’t just about aesthetics, it’s about accuracy. Learn how understanding Field of View (FOV) can help you avoid blind spots, reduce rework, and confidently plan your construction time-lapse setup.

- Camera Setup

- Construction

- Construction Monitoring

- Construction Photos

- Construction Time Lapse

- DataLens

- SolarUp

- August 15, 2025

- 4 min read

Not all visibility methods are created equal. While live streaming sounds powerful, it drains budgets, bandwidth, and power. This post breaks down the real differences between live video, live view, and on-demand photo access, helping construction teams choose the smartest, most efficient way to monitor their jobsites.

- July 30, 2025

- 3 min read

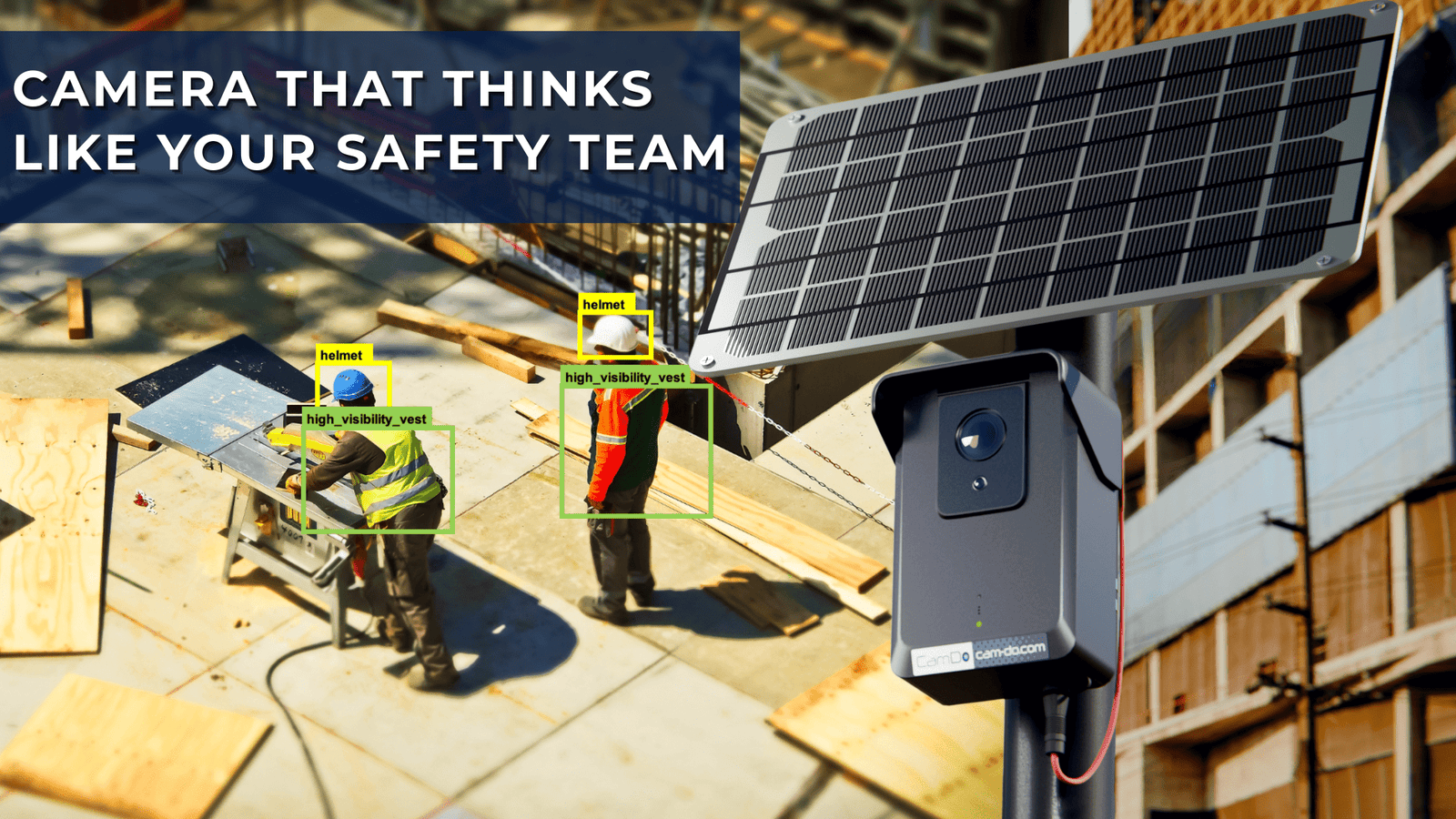

Discover how one plug-and-play camera is reshaping jobsite monitoring. From 4K time-lapse to AI-powered safety alerts, this all-in-one solution helps construction teams reduce delays, cut site visits, and stay fully connected, no matter the location.

- June 25, 2025

- 5 min read

GoPro cameras have evolved far beyond their action-sports roots. In this post, we clear up 7 common misconceptions, from video quality to long-term automation, and explore why GoPros are now trusted in industries like construction and research.

- AI Monitoring

- Camera Setup

- Cloud

- CloudX

- Construction Monitoring

- GoPro Time Lapse

- Photography

- Time Lapse

- Tips

- June 05, 2025

- 3 min read

- May 23, 2025

- 3 min read